¿Cuál es el propósito de la máquina de techo de celda abierta?

2025-01-12 14:15

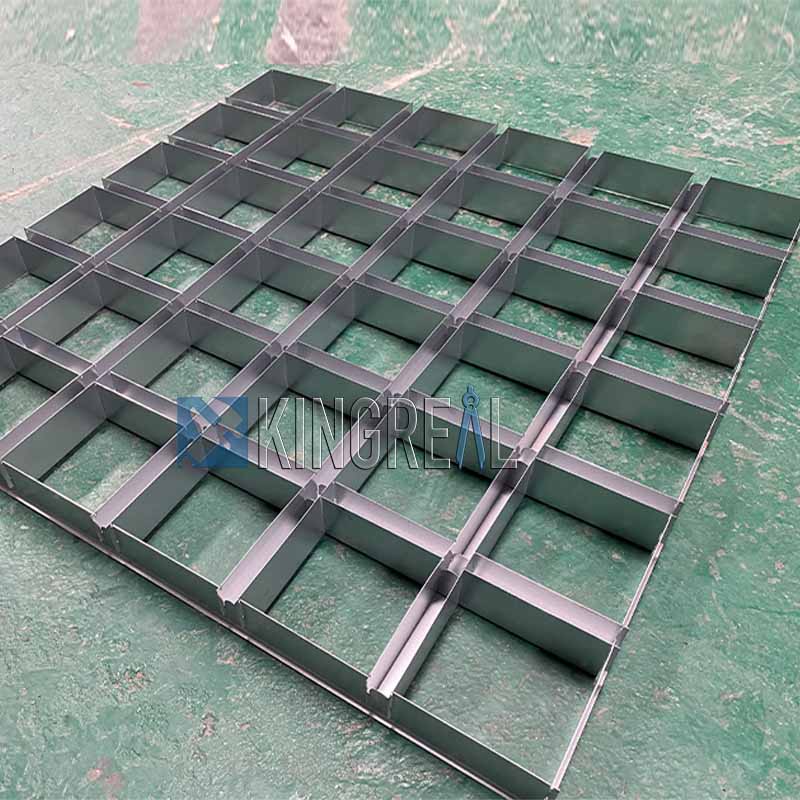

El techo de rejilla es una estructura de diseño de rejilla abierta, ideal para la decoración de techos metálicos en grandes centros comerciales, clubes de ocio, bares, aeropuertos, edificios de oficinas y otros lugares. Este techo de celda abierta elimina las deficiencias del tipo tradicional, como la dificultad de instalación y desmontaje, y la deformación de la quilla. Es popular entre los profesionales de la decoración por sus capas transparentes, su gran tridimensionalidad, su forma innovadora, su resistencia al fuego y a la humedad, su buena ventilación y otras características.

Entre ellos, el Máquina formadora de rollos para techos de rejilla Es un equipo mecánico especialmente diseñado para la producción de techos de rejilla. Permite transformar láminas metálicas (generalmente de aluminio o acero) en productos para techos con estructuras de celdas abiertas mediante procesos como desenrollado, nivelado, punzonado, corte y conformado. Esta máquina para techos de celdas abiertas no solo mejora la eficiencia de producción, sino que también garantiza la alta precisión y estabilidad del producto, lo que le confiere una amplia gama de aplicaciones en la industria de los techos. |  |

Componentes principales de la máquina de techo de celda abierta

Desenrollador

El primer componente de la máquina perfiladora de techos de rejilla es el desbobinador. La bobina metálica se coloca en el desbobinador para su desenrollado automático.

Plancha de precisión

El enderezador de precisión se utiliza para garantizar que la superficie de la bobina de metal después del desenrollado sea plana y corregir cualquier posible deformación.

Estación de perforación

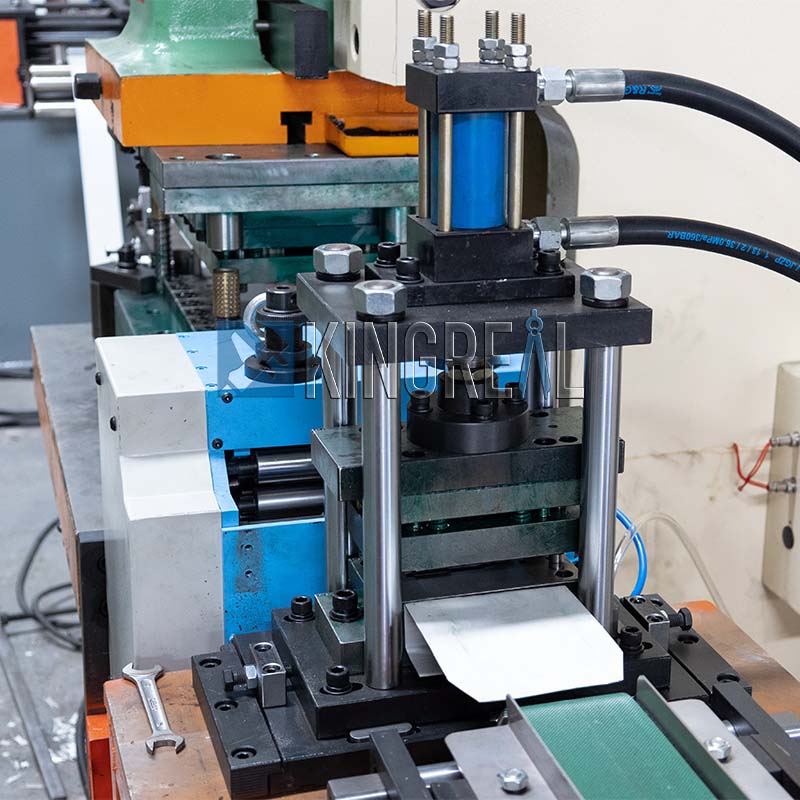

La bobina de metal se envía a la estación de punzonado para su troquelado. Existen dos tipos de punzonadoras para las diferentes necesidades de producción de los clientes.

Estación de corte

La estación de corte cortará de forma inteligente según la longitud requerida por el cliente.

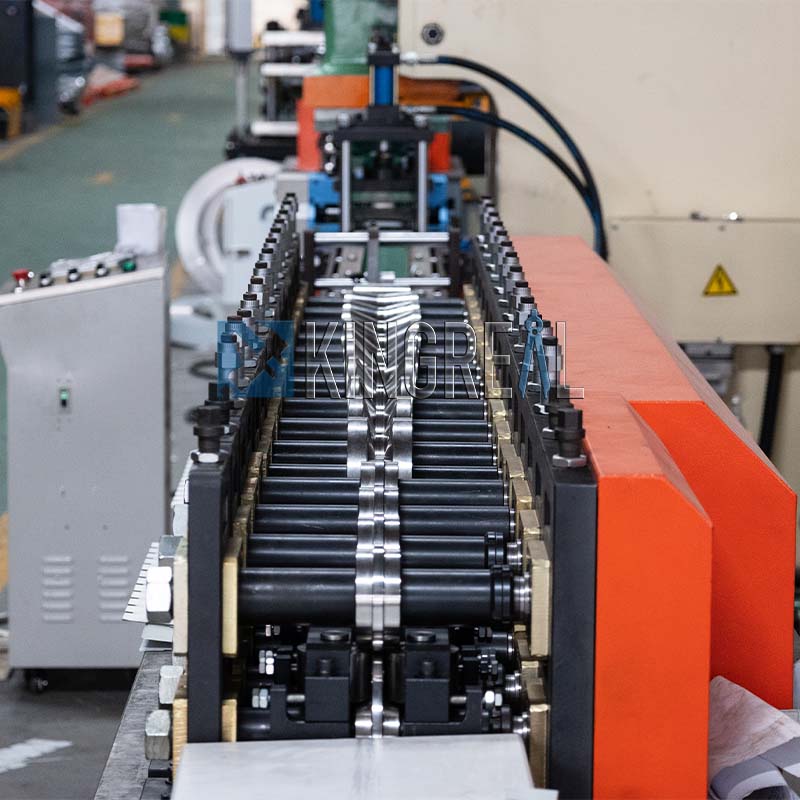

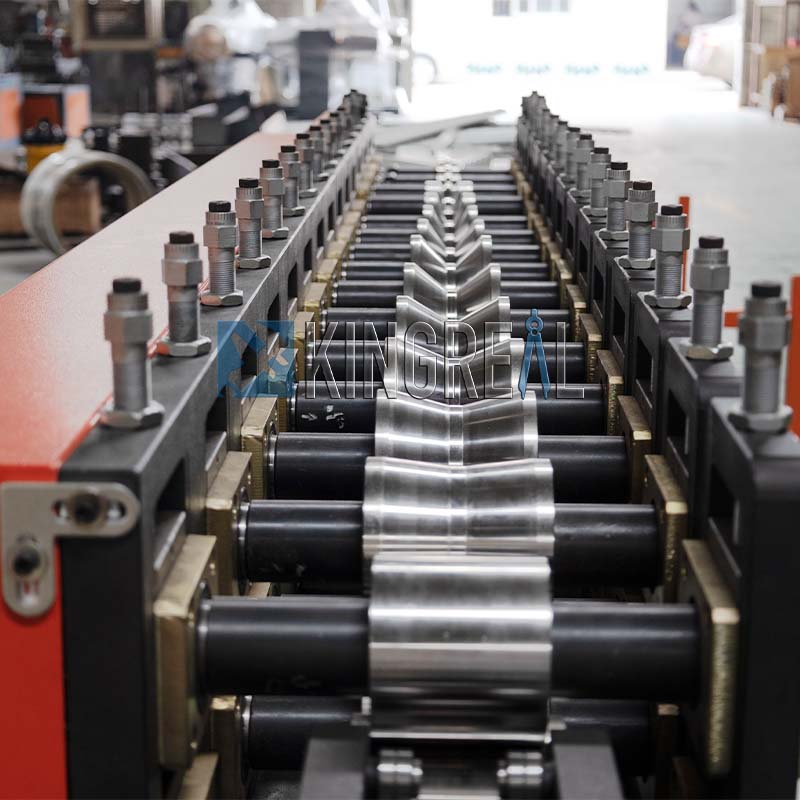

Máquina formadora de rollos

Ajustando el espacio y la presión de los rodillos, la chapa metálica se prensa gradualmente hasta adquirir la forma de rejilla requerida.

Mesa de descarga

Después de que el techo de celda abierta pasa por una serie de procesos de trabajo previos, se finaliza la producción y se descarga el material.

Vídeo sobre la máquina de techo de celda abierta

Ventajas de la máquina de techo de celda abierta

1. Máquina de techo de celda abierta de alta velocidad

| La máquina perfiladora de techos tipo grillato KINGREAL CEILING MACHINERY tiene una velocidad de formación rápida, que puede alcanzar hasta 30 m/min, y la velocidad se puede ajustar de acuerdo con las necesidades de producción reales. |  |

2.Dos modelos de opciones

El estándar de MAQUINARIA DE TECHOS KINGREALmáquina de techo de celda abierta está equipado con un16 toneladasMáquina perforadora, que solo puede perforar un agujero a la vez. En comparación con la perfiladora de techos de rejilla estándar, la perfiladora de techos de rejilla de alta gama mejora la estación de perforación a una63 toneladasEstación de punzonado, que permite realizar el punzonado del producto en una sola pasada. Mejora considerablemente la eficiencia de producción y la precisión del producto.

3.Ajuste automático del ancho

| El ancho de la máquina para techos de celdas abiertas KINGREAL CEILING MACHINERY se puede ajustar mediante el sistema CNC, y el operador puede cambiar automáticamente el ancho, la altura y la longitud del producto para producir rejillas de diferentes tamaños. |  |

4.Las materias primas metálicas son compatibles

La máquina perfiladora de techos grillato puede ser compatible con amboshierroyaluminioSe pueden producir materias primas metálicas y dos techos de rejilla de diferentes materiales con una sola línea de producción. Esto evita las molestias de cambiar de línea y ajustar la producción.

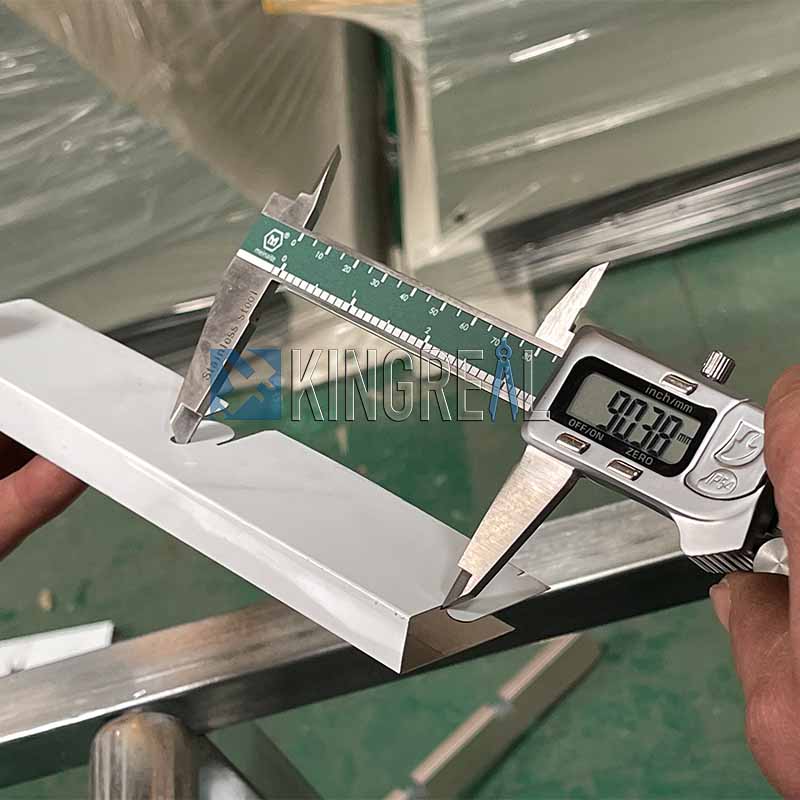

5. Máquina de techo de celda abierta de alta precisión

El sistema de control de precisión de la máquina perfiladora de techos de rejilla garantiza la consistencia del tamaño y la forma de cada techo de celda abierta, evitando defectos o productos no cualificados. Las máquinas para techos de celda abierta de KINGREAL CEILING MACHINERY garantizan un margen de error de precisión del producto terminado.±0,1 mm.

6. Máquina de techo de celda abierta altamente automática

| La máquina para techos de celdas abiertas KINGREAL CEILING MACHINERY adopta un sistema de control PLC, que puede monitorear automáticamente el proceso de producción, ajustar automáticamente el estado de operación de la máquina, reducir los errores humanos y las fluctuaciones de producción y garantizar la estabilidad y eficiencia de la producción. |  |

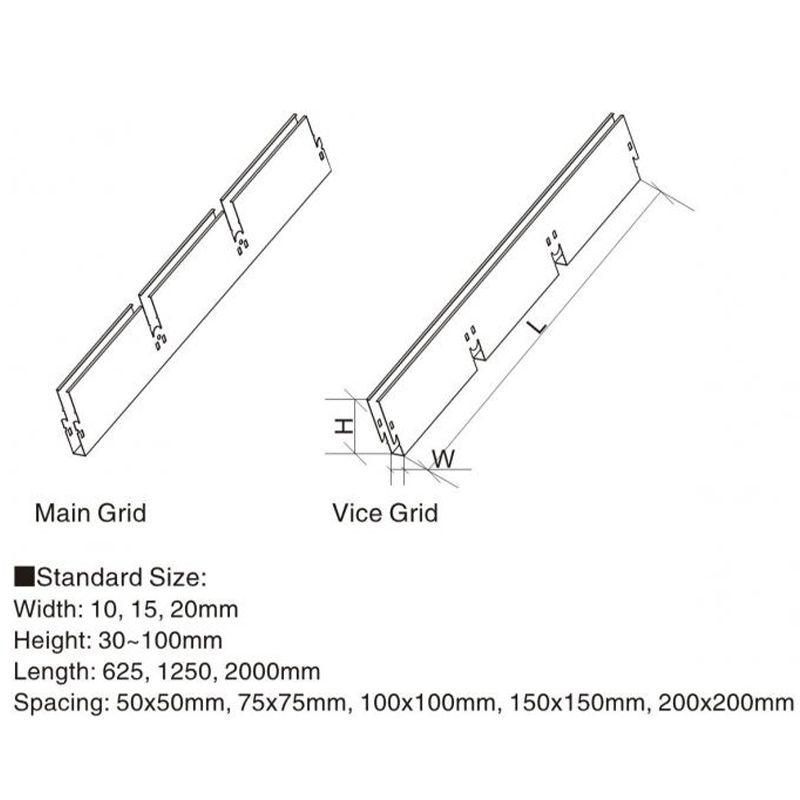

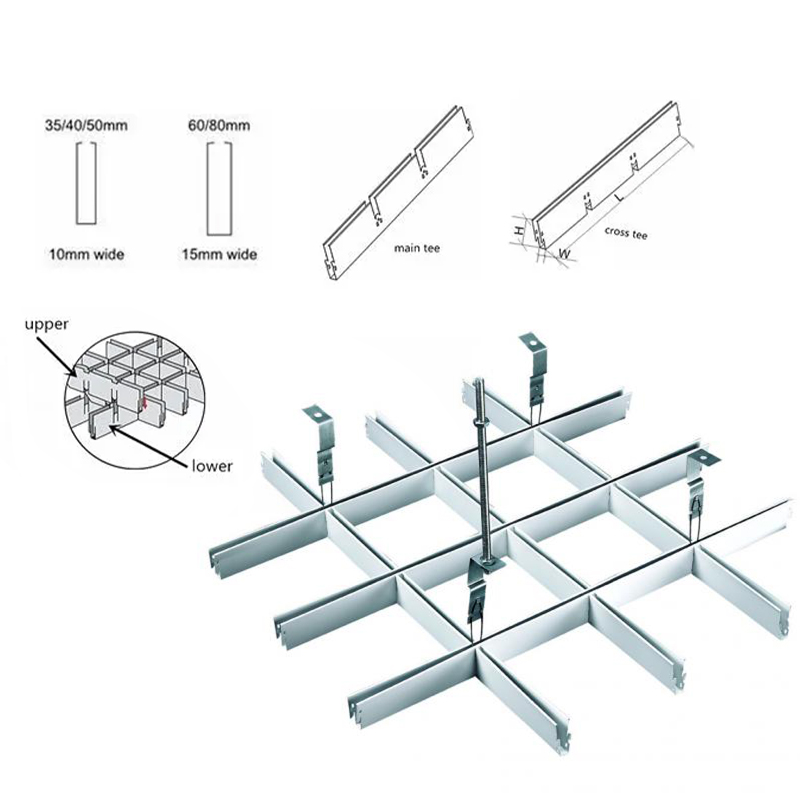

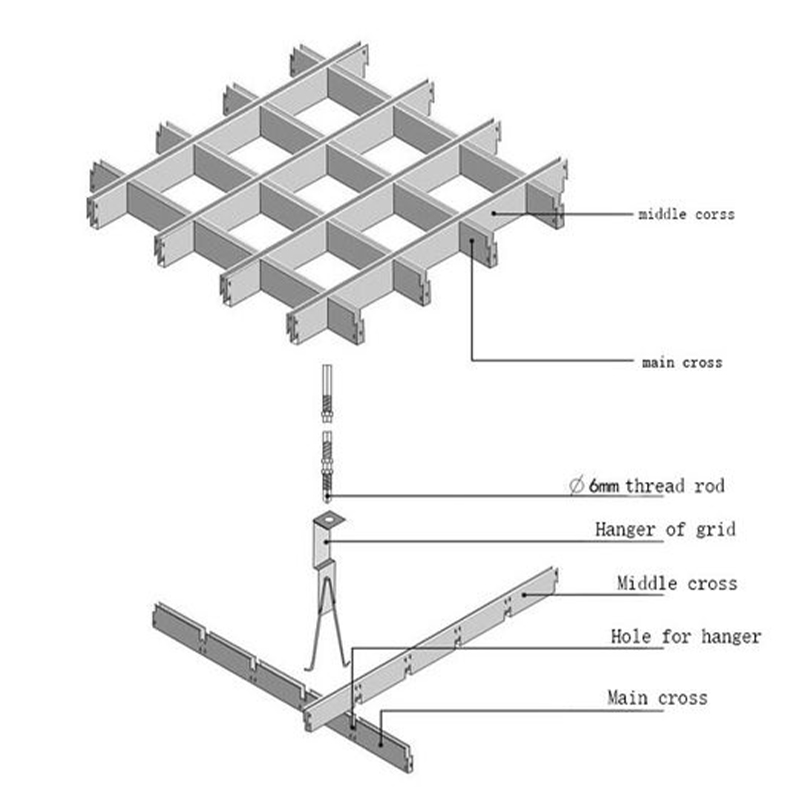

Dibujo sobre el techo de celda abierta

Obtenga el último precio? Le responderemos lo antes posible (dentro de las 12 horas)