Máquina perforadora de chapa metálica

KINGREAL CEILING MACHINERY puede proporcionar soluciones de fabricación de máquinas perforadas de láminas de metal personalizadas según las necesidades del cliente, y KINGREAL CEILING MACHINERY puede proporcionar diferentes tipos de máquinas para satisfacer las diferentes aplicaciones de los clientes para láminas perforadas.

- KINGREAL CEILING MACHINERY

Detalles

Vídeo sobre la máquina perforadora de chapa metálica

Definición de máquina perforadora de chapa metálica

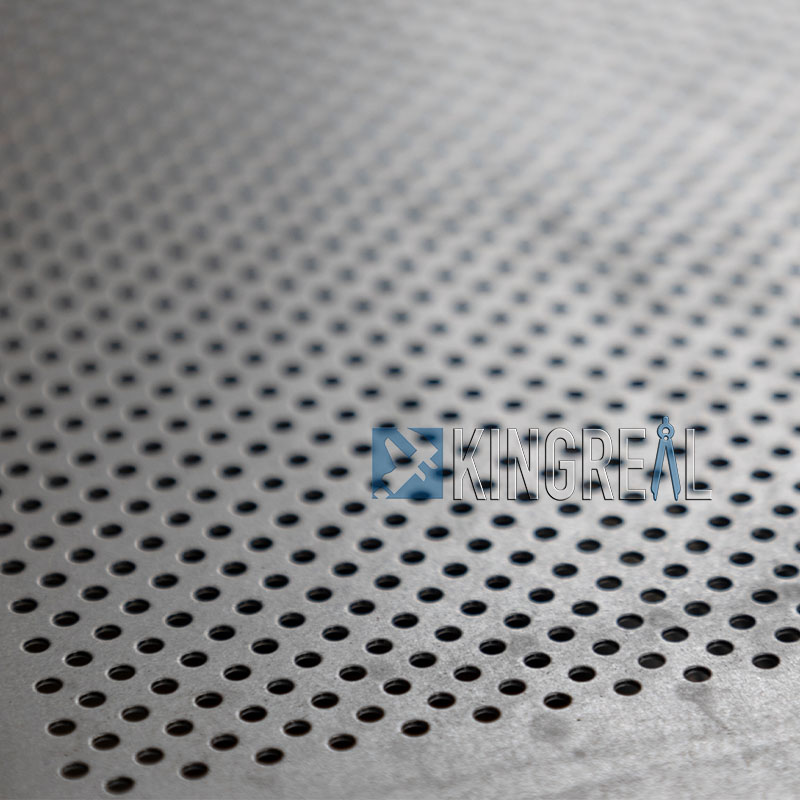

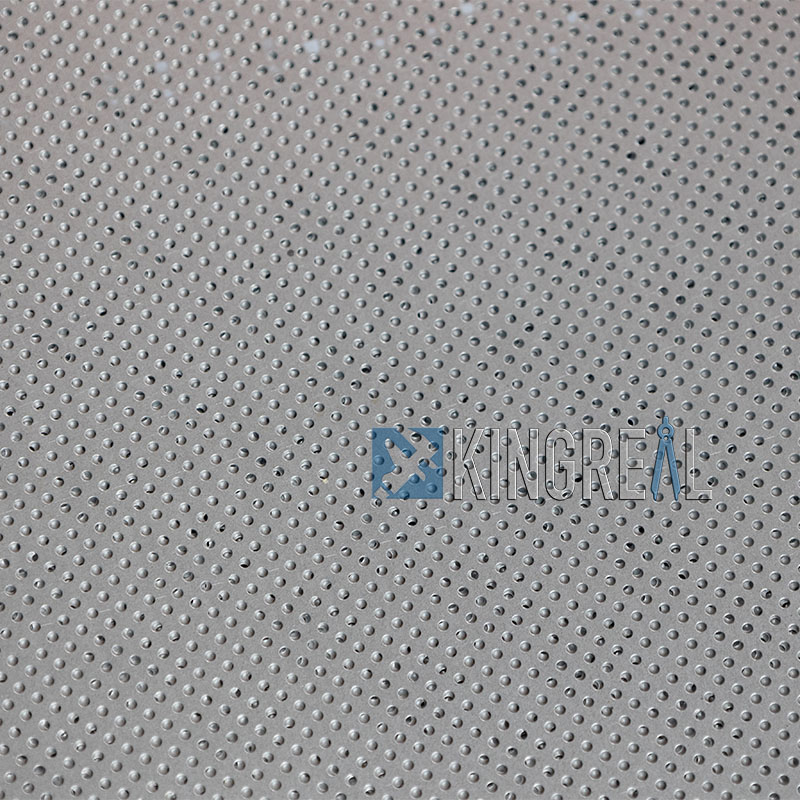

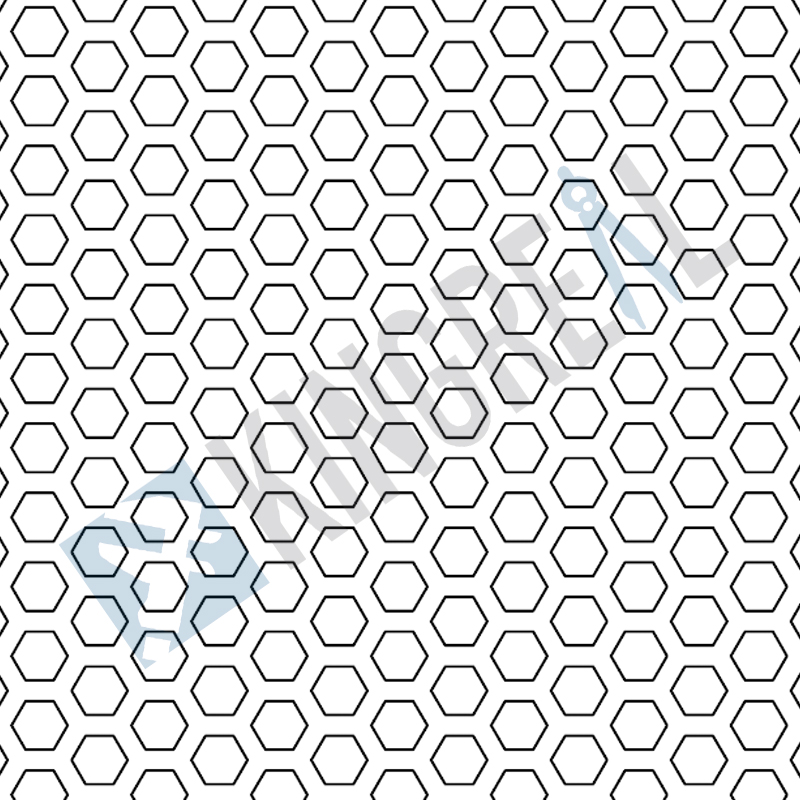

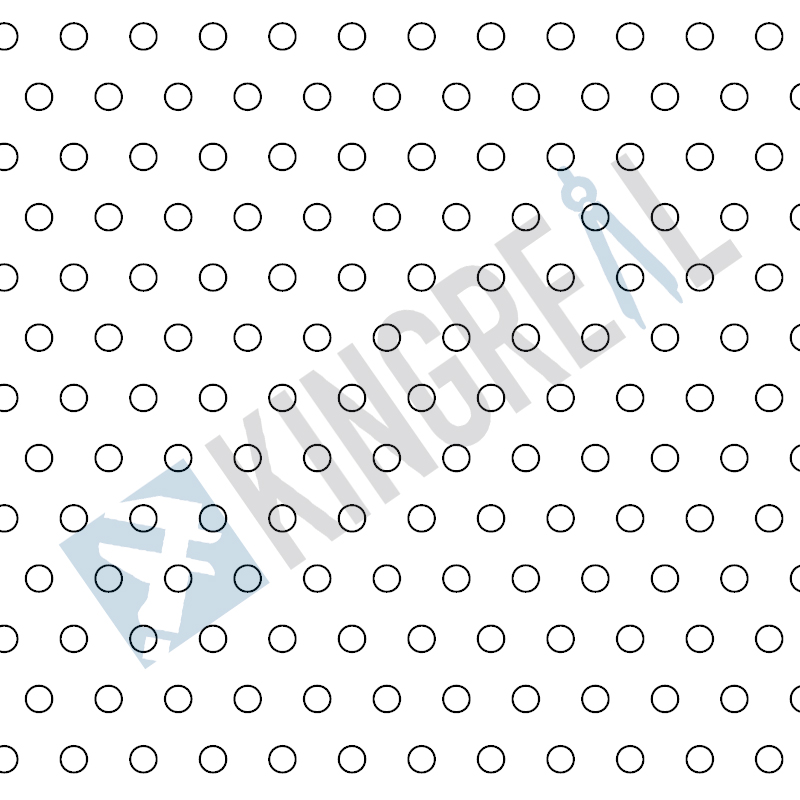

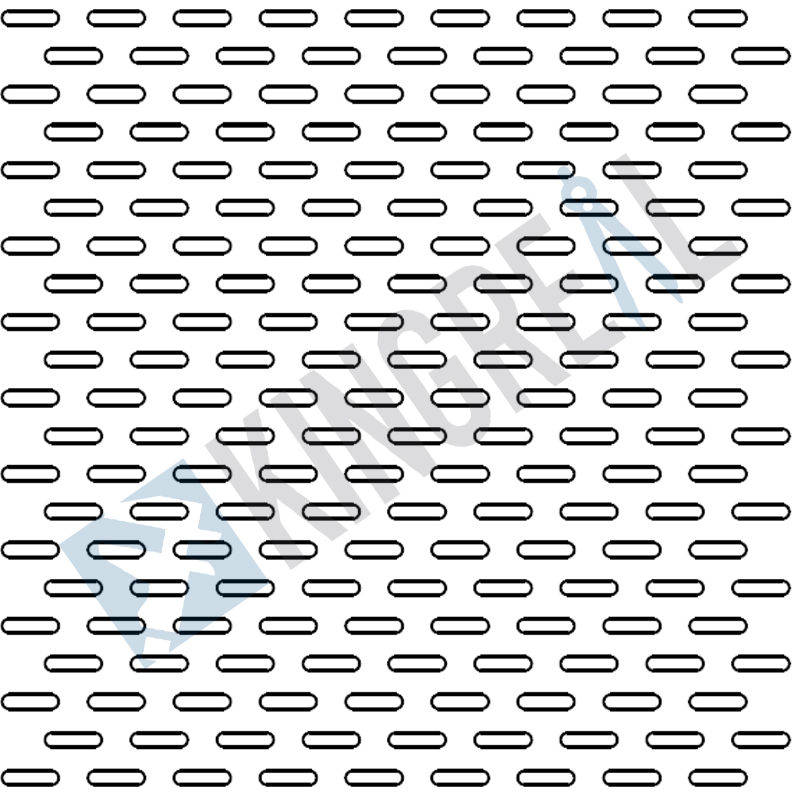

La máquina perforadora de chapa metálica es un dispositivo especialmente diseñado para procesar chapas metálicas de diferentes materiales con el tipo de orificio requerido, y se utiliza generalmente para fabricar diversas chapas perforadas. La diversidad de diseños de orificios satisface diferentes necesidades industriales. Los tipos de orificios más comunes incluyen orificios redondos escalonados, orificios redondos rectos, orificios hexagonales escalonados, orificios rectos cuadrados y orificios redondos escalonados con ranura. El diseño de estos orificios no solo afecta la apariencia del producto, sino que también está directamente relacionado con su funcionalidad y aplicación. Durante el proceso de punzonado, la chapa metálica se perfora con precisión a través de la máquina perforadora para formar orificios de formas y tamaños específicos. Este proceso no solo mejora la permeabilidad, la resistencia y la estética del material, sino que también sienta las bases para el posterior procesamiento secundario. Mediante el punzonado, se reduce el peso de la chapa metálica, manteniendo la estabilidad de la estructura, lo que le confiere un excelente rendimiento en diversas aplicaciones.

Tras el punzonado, las láminas metálicas suelen utilizarse en diversas industrias para su posterior procesamiento secundario y la formación del producto final. Estas láminas perforadas se utilizan ampliamente en diversos campos, como la decoración arquitectónica, los equipos industriales, el procesamiento de alimentos, la industria química farmacéutica, la protección del medio ambiente y la energía, entre otros. La amplia aplicación de las máquinas perforadoras de láminas metálicas las convierte en una herramienta esencial en numerosas industrias. Su diverso diseño de orificios y su eficiente capacidad de procesamiento las convierten en una herramienta clave para satisfacer las necesidades de la fabricación moderna.

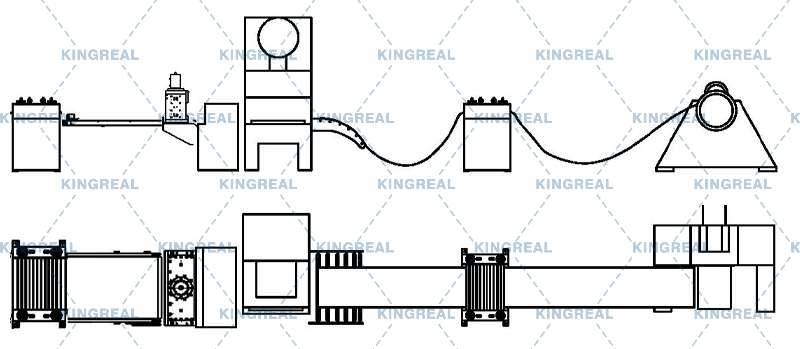

Proceso de trabajo de la máquina perforadora de chapa metálica

Desenrollador - Enderezador de precisión - Punzonadora - Estación de corte

Parámetros generales de la máquina perforadora de chapa metálica

Ancho de la bobina

El ancho de la bobina se puede personalizar según las necesidades específicas del cliente. Este diseño flexible satisface las necesidades específicas de cada cliente.

Espesor del material

Normalmente, la máquina perforadora de chapa metálica puede procesar bobinas de metal con un espesor de 0,4 a 1,0 mm. Si necesita bobinas con un espesor especial, consulte con KNGREAL CEILING MACHINERY.

Peso de la bobina

Las máquinas perforadoras de chapa metálica KINGREAL CEILING MACHINERY pueden manejar bobinas de metal que pesan hasta 5 toneladas.

Panel de control PLC inteligente

Tiene sistemas de múltiples idiomas, como inglés, español, ruso, árabe, etc., y puede ingresar parámetros de producción y ajustar la velocidad de la máquina perforadora de chapa metálica en el panel de control.

Aplicación de la máquina perforadora de chapa metálica

Como equipo clave para el procesamiento de materiales metálicos, las máquinas perforadoras de chapa metálica se utilizan ampliamente en diversas industrias, como la construcción, la industria y la química, y son valoradas por su eficiencia y precisión en la fabricación de chapas perforadas. En la industria moderna, las chapas perforadas, como material básico importante, se utilizan ampliamente en campos como piezas estructurales, filtros, equipos de ventilación y materiales decorativos.

Con el continuo avance de la tecnología industrial, muchas industrias exigen cada vez más calidad y precisión en las chapas perforadas, especialmente en cuanto a la precisión del tamaño de la abertura y la calidad del borde del orificio. Estos requisitos no solo afectan el rendimiento general y la estética del producto, sino que también pueden tener un profundo impacto en su posterior procesamiento y uso.

Para satisfacer las cambiantes necesidades del mercado, las máquinas perforadoras de chapa metálica de KINGREAL CEILING MACHINERY se esfuerzan por alcanzar la innovación tecnológica y un nivel profesional. Mediante la introducción de tecnología de punzonado avanzada y sistemas de control de alta precisión, el proceso de producción se optimiza continuamente para garantizar que cada chapa perforada cumpla con los estándares de la industria y las necesidades específicas del cliente.

Diferentes tipos de máquinas perforadoras de metal

De acuerdo con las aplicaciones de procesamiento secundario posteriores de láminas perforadas en diferentes industrias, KINGREAL CEILING MACHINERY ofrece tres tipos de máquinas perforadas de metal: máquina perforadora de láminas de metal, línea de perforación de bobina a bobina y línea de perforación de placas de techo de metal.

Al reemplazar la matriz de punzonado, la máquina perforadora de metal KINGREALCEILING MACHINERY puede producir con flexibilidad láminas metálicas con diferentes diámetros y formas de orificios sin necesidad de reemplazar o volver a poner en funcionamiento el equipo. Este eficiente método de operación no solo ahorra costos de inversión en equipos, sino que también reduce considerablemente el tiempo de preparación para la producción.

●Máquina perforadora de chapa metálica

La máquina perforadora de chapa metálica se utiliza específicamente para cortar chapas metálicas según las necesidades específicas del cliente tras el punzonado. Mediante este proceso, se forman chapas perforadas estandarizadas, lo que facilita su posterior procesamiento y uso.

★ Flujo de trabajo:Desbobinador hidráulico - Enderezador de precisión - Punzonadora - Máquina de alimentación servo - Cizalla

★ Componentes destacados de la línea de perforación de chapa metálica

Estación de corte para máquina perforadora de chapa metálica:

La máquina perforadora de chapa metálica KINGREAL CEILING MACHINERY, equipada con estación de corte, utiliza cuchillas de materiales de alta dureza para garantizar la planitud de la superficie de corte de la chapa tras el corte. Este diseño no solo mejora la calidad del corte, sino que también prolonga la vida útil de la cuchilla. Además, la estación de corte está controlada por un equipo altamente inteligente para garantizar que la longitud real del corte coincida con la longitud preestablecida, evitando así irregularidades causadas por errores de operación.

★ Aplicación para máquina perforadora de chapa metálica

Las placas perforadas procesadas por la máquina perforadora de chapa metálica se utilizan generalmente en la fabricación de una variedad de productos, como sillas, paneles de pared, barandillas de balcones, mamparas, escaleras, cestas, cestas de lavado, parrillas, reactores, etc. Estos productos terminados juegan un papel importante en la decoración arquitectónica, la fabricación de muebles y equipos industriales.

●Bobina a bobinapaglínea de perforación

La línea de perforación de bobina a bobina enrolla la placa metálica a través de la rebobinadora tras el punzonado. Este proceso no solo facilita el transporte y almacenamiento, sino que también optimiza el proceso de fabricación.

★ Flujo de trabajo:Desbobinador hidráulico - Enderezador de precisión - Punzonadora - Máquina de alimentación servo - Rebobinador hidráulico

★ Componentes destacados de la línea de perforación de bobina a bobina

(1)Máquina de limpieza de chapa metálica para línea de perforación de bobina a bobina:

KINGREAL CEILING MACHINERY ha incorporado de forma innovadora una máquina limpiadora de láminas metálicas a la línea de perforación de bobina a bobina con rebobinado. Tras el proceso de punzonado anterior, la placa metálica puede dejar manchas en la superficie. La máquina limpiadora de láminas metálicas puede eliminar estas manchas eficazmente y proporcionar una superficie limpia para el procesamiento posterior. Este diseño ahorra tiempo en el procesamiento posterior y mejora la eficiencia de la producción.

(2) Enrollador para línea de perforación de bobina a bobina:

La rebobinadora es uno de los equipos principales de la línea de perforación de bobina a bobina. Está diseñada para mejorar la eficiencia del procesamiento y la comodidad de almacenamiento de las chapas metálicas perforadas. Al enrollarlas cuidadosamente, la rebobinadora no solo optimiza el uso del espacio, sino que también facilita su posterior transporte y procesamiento.

★ Aplicación para línea de perforación de bobina a bobina

Las placas perforadas procesadas por la línea de perforación de bobina a bobina se utilizan generalmente para fabricar elementos filtrantes, bandejas de pan, paneles de ventilación y disipación de calor, filtros, pantallas, separadores, cubiertas protectoras de equipos de energía eólica, soportes para paneles solares, etc. Estos productos tienen una amplia gama de aplicaciones en industrias como la protección del medio ambiente, la energía y el procesamiento de alimentos.

● Línea de perforación de placas de techo metálicas

La línea de perforación de placas metálicas para techos es un dispositivo diseñado para satisfacer necesidades específicas de decoración arquitectónica. Se puede utilizar junto con la máquina para fabricar placas metálicas para techos KINGREAL CEILING MACHINERY para producir diferentes tamaños y tipos de placas perforadas, como las habituales de 30 x 30 cm, 60 x 60 cm y 60 x 120 cm, así como diferentes tipos como clip-in, lay-in, tegular, etc.

★ Flujo de trabajo:Desbobinador hidráulico - Enderezador de precisión - Punzonadora - Servoalimentadora - Prensa de entallado y corte

★ Componentes destacados de la línea de perforación de techos metálicos

Entallado y prensado para línea de perforación de placas de techo metálicas:

Tras el punzonado, la lámina metálica se introduce en la máquina de entallado y prensado. Este equipo corta las cuatro esquinas de la lámina y realiza un corte preliminar para formar el prototipo del techo. Este proceso no solo mejora la eficiencia de producción, sino que también garantiza que los bordes del techo queden planos, lo que facilita su posterior instalación y uso.

★ Aplicación para línea de perforación de placas de techo metálicas

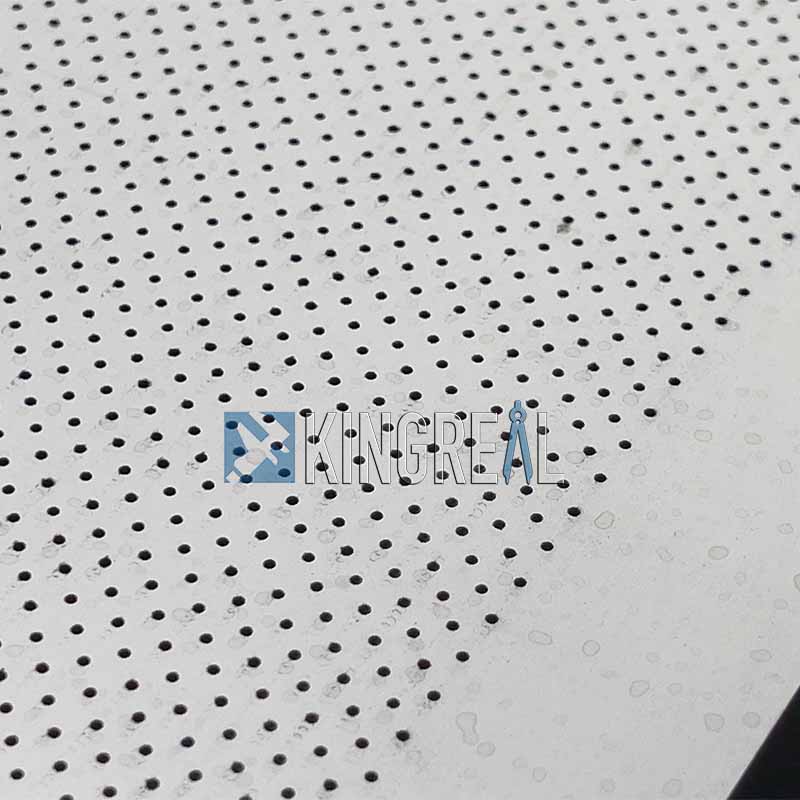

El techo perforado tiene una apariencia atractiva y un buen efecto decorativo. Además, gracias a la presencia de numerosos orificios pequeños, el sonido puede pasar a través de ellos, atenuando su intensidad y reduciendo el ruido adecuadamente.

Características de la máquina perforadora de chapa metálica

Nivelador de precisión para máquina perforadora de chapa metálica

La máquina perforadora de chapa metálica KINGREAL CEILING MACHINERY está equipada con un nivelador de precisión de alto rendimiento, compuesto por 4 ruedas superiores y 5 inferiores que conforman un dispositivo de aplanamiento profesional de 9 rodillos. El objetivo principal de este diseño es nivelar eficazmente la bobina metálica para garantizar una superficie lisa y sin ondulaciones. Mediante el proceso de aplanamiento multivuelta, el material metálico puede moldearse completamente antes de la etapa de punzonado, lo cual es crucial para mejorar la precisión del punzonado.

El funcionamiento eficiente de la aplanadora no solo elimina la flexión y deformación de la bobina durante el almacenamiento y el transporte, sino que también reduce significativamente los errores generados en el proceso de punzonado posterior. Este proceso de aplanado de alta precisión permite que el producto punzonado tenga mayor consistencia en tamaño y forma, reduce la tasa de desperdicios causada por materiales irregulares y, por lo tanto, mejora la eficiencia de producción del cliente y la competitividad del producto final en el mercado.

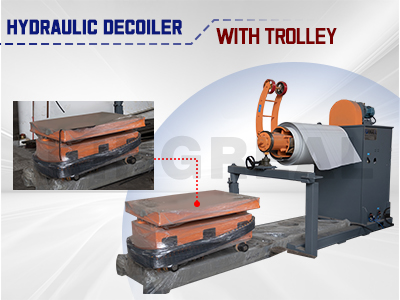

Desbobinador con carro de alimentación para máquina perforadora de chapa metálica

Para optimizar la automatización de la máquina perforadora de chapa metálica, KINGREAL CEILING MACHINERY equipó la desbobinadora con un carro de alimentación. Este diseño innovador hace que el manejo de bobinas metálicas sea más eficiente y cómodo. Los clientes solo tienen que colocar la bobina en el carro de alimentación y el sistema la transportará automáticamente a la desbobinadora para completar las operaciones de desbobinado y punzonado.

La introducción de este sistema de alimentación automática reduce significativamente los costos de mano de obra y la carga de trabajo de los operarios. Al mismo tiempo, optimiza el tiempo y garantiza la continuidad y fluidez del proceso de producción. Al reducir la intervención manual, la máquina perforadora de chapa metálica KINGREAL CEILING MACHINERY reduce la posibilidad de errores humanos durante la operación, lo que aumenta la estabilidad y la fiabilidad del proceso de producción.

Inspección de calidad

Los productos fabricados por la máquina perforadora de chapa metálica KINGREAL CEILING MACHINERY satisfacen plenamente las necesidades de producción de los clientes, con alta precisión, sin rebabas en la superficie y un tamaño de orificio constante. Por lo tanto, los productos de buena calidad se pueden utilizar mejor en el procesamiento secundario y la fabricación. Esta es también la opinión más frecuente de los clientes sobre la máquina perforadora de chapa metálica KINGREAL CEILING MACHINERY.

¿Qué puede proporcionar KINGREAL CEILING MACHINERY?

| (1) Soluciones personalizadas KINGREAL CEILING MACHINERY se centra en ofrecer a sus clientes soluciones de fabricación de máquinas perforadoras de chapa altamente personalizadas, diseñadas para satisfacer las necesidades específicas de diferentes industrias y clientes. A medida que el mercado continúa desarrollándose, los clientes exigen mayores exigencias en cuanto al rendimiento y la flexibilidad de las máquinas perforadoras de chapa. Para ayudar a los clientes a destacarse en un entorno altamente competitivo, KINGREAL CEILING MACHINERY se compromete a brindar soluciones a medida para garantizar que cada máquina perforadora de chapa metálica pueda adaptarse perfectamente a las necesidades de producción reales de los clientes. Durante todo el proceso de personalización, el equipo de ingeniería profesional de KINGREAL CEILING MACHINERY se comunicará en profundidad con los clientes para comprender a fondo sus procesos de producción, las especificaciones de sus productos y las necesidades del mercado. Con base en los planos y los requisitos específicos proporcionados por los clientes, el equipo realizará un análisis exhaustivo y discutirá con ellos para desarrollar el plan de producción más adecuado. |

(2) Máquina perforadora de chapa metálica de alta calidad Durante el proceso de fabricación de la máquina perforadora de chapa metálica, KINGREAL CEILING MACHINERY siempre cumple con altos estándares de calidad. Desde la selección de las materias primas, KINGREAL CEILING MACHINERY implementa un estricto proceso de inspección y utiliza exclusivamente materiales de alta calidad para garantizar la durabilidad y fiabilidad de la máquina perforadora de chapa metálica. Durante el proceso de fabricación, KINGREAL CEILING MACHINERY cuenta con un equipo técnico profesional para supervisar todo el proceso para garantizar que cada máquina perforadora de láminas de metal enviada a la fábrica del cliente cumpla con los estándares de la industria y las expectativas del cliente. Este estricto control de calidad ha hecho que las máquinas perforadoras de chapa metálica de KINGREAL CEILING MACHINERY sean ampliamente elogiadas en el mercado. Los clientes afirman que los equipos de KINGREAL CEILING MACHINERY ofrecen una alta rentabilidad, bajos costos de mantenimiento y una durabilidad excepcional. Esta máquina perforadora de chapa metálica de alta calidad permite a los clientes mantener una capacidad de producción eficiente durante el uso a largo plazo, logrando así el mejor equilibrio entre costo y beneficio. |  |

| (3)Servicio posventa El equipo de posventa de KINGREAL CEILING MACHINERY está compuesto por un grupo de profesionales altamente capacitados que no solo poseen sólidos conocimientos técnicos, sino también una amplia experiencia en el campo. Ya sea la puesta en marcha de equipos, la resolución de problemas o el mantenimiento diario, lo gestionan con eficiencia y profesionalismo. Cuando la máquina perforadora de chapa metálica presenta una falla, el equipo de posventa puede identificar el problema lo antes posible y realizar un análisis detallado para garantizar que el equipo vuelva a funcionar con normalidad lo antes posible. Gracias a su rápida respuesta, KINGREAL CEILING MACHINERY ayuda a los clientes a minimizar el tiempo de inactividad y a garantizar la continuidad y estabilidad de la máquina perforadora de chapa metálica. |

Dibujos sobre cómo hacer un agujero

¿Cómo obtener soluciones de máquinas perforadoras de chapa metálica?

Envíe sus requisitos de producción a KINGREAL CEILING MACHINERY y tendremos personal profesional que se comunicará con usted para comenzar la personalización.

1. Espesor de la bobina

2.Ancho de la bobina

3.Material de la bobina

4.Diseño de perforación

producto del tag

Obtenga el último precio? Le responderemos lo antes posible (dentro de las 12 horas)